Our Magic Kingdom- Wonder in New Gretna

As seen in Viking’s “The Viking View”, learn more about how Viking is an unmatched builder in the marine industry.

The Viking Yacht Company will build upwards of 70 yachts this year at its New Gretna, New Jersey, manufacturing plant. The scope and diversity of our fleet remain unmatched in the industry. We offer 35 different models from 38 to 93 feet that include open, enclosed, and sky bridge convertibles; express and sport boats; the Billfish series; and motor yachts. The Viking View over the next few months will take a close look at each of the four manufacturing lines. You’ll see the boats being built, of course, but also meet our shipwrights and managers while getting some interesting inside info. Our boatbuilding facility is commonly referred to as a Disneyland for boating enthusiasts, so welcome to our Magic Kingdom.

Each manufacturing line is about a quarter of a mile long – that’s the length of nearly 4-1/2 football fields! Lines 1 and 2 are dedicated to our larger yachts from 62 to 93 feet, while boats from 38 to 58 feet are built on lines 3 and 4. Each manufacturing department (such as Viglass, Mechanical, Electrical, Carpentry, Interior/Exterior Trim and the Make Ready Dock) is dedicated to a particular stage of the build process. The build begins in Viglass (our fiberglass department), where the hulls are fabricated using the resin infusion process and then pulled from their molds, as shown above with this 62 Convertible.

Viglass also builds many other large fiberglass structures, such as deckhouses, bridges and fiberglass fuel tanks, as well countless small parts. Above: Shipwrights guide the deckhouse of a 68 forward on Line 1 from Viglass (left) into Mechanical (right) where it will be lowered onto its awaiting hull.

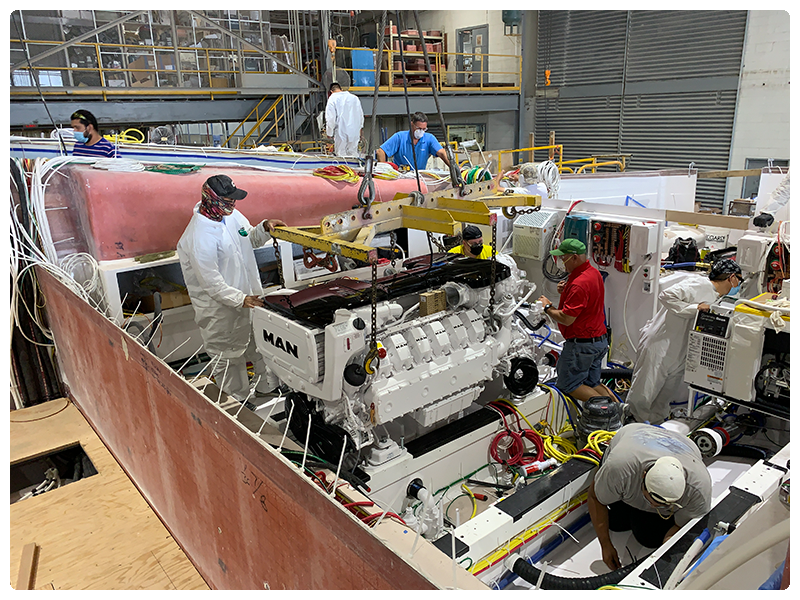

Each department is led by a supervisor (blue shirt), foreman (red shirt) and leadman (yellow shirt). Above left: On Line 4, Mechanical Supervisor Steve Rickards, Foreman Bill Langel and a team of shipwrights install the first of two 1550MHP V12 MAN diesels into a 54 Convertible. Above right: Using a handheld control, Leadman Pete Skudalski Jr. (a second-generation Viking employee whose father worked here for 47 years) operates the overhead electric hoist to “fly” the second engine into the boat.

Viking has a tremendous facility in terms of size and technology, but our people (1,225-strong) are the lifeblood of the company. “We’re all pulling in one direction to build a better boat every day,” says Sergio Fernandez, a painter in the Exterior Trim Department. Sergio is shown (left) buffing the custom black mask of an 80 Convertible on Line 2. The black mask on a large Viking like this takes two to three days and entails the application of multiple coats of primer, base and clear coats with extensive sanding and buffing. “Yes, it’s hard work,” says Sergio, who in his spare time designs automotive graphic art and enjoys photography. “But creating something beautiful that you’re proud of is never easy.” With that job behind him – literally and figuratively – Sergio transitioned over to Line 1 to work on our next 75 Motor Yacht shown below.