Description

Bad Girl is a 186.02ft /56.7m motor yacht, launched in 1992 by Brooke Marine. Previously named Chamar, her impressive interior is by Luigi Sturchio, and her exterior styling is by Don Shead Yacht Design.

Bad Girl’s interior layout sleeps up to 12 guests in 7 rooms, including a master suite, 3 double cabins and 3 twin cabins. She is also capable of carrying up to 15 crew onboard to ensure a relaxed luxury yacht experience.

Disclaimer

HMY Yacht Sales, Inc. is pleased to assist you in the purchase of this vessel. This boat is centrally listed by IKONIC YACHTS.

Specifications

Vessel Overview

BAD GIRL (formerly CHAMAR) is a luxury yacht built by the respected builders Brooke Yachts UK, measuring 56.7m (186 feet) in length, and accommodating up to 12 guests in 6 beautiful staterooms. Her interior design is by Luigi Sturchio and her exterior design by Don Shead.

BAD GIRL’s distinctive design combines modern and classic elegance, with outstanding performance to ensure a truly extraordinary cruising experience.

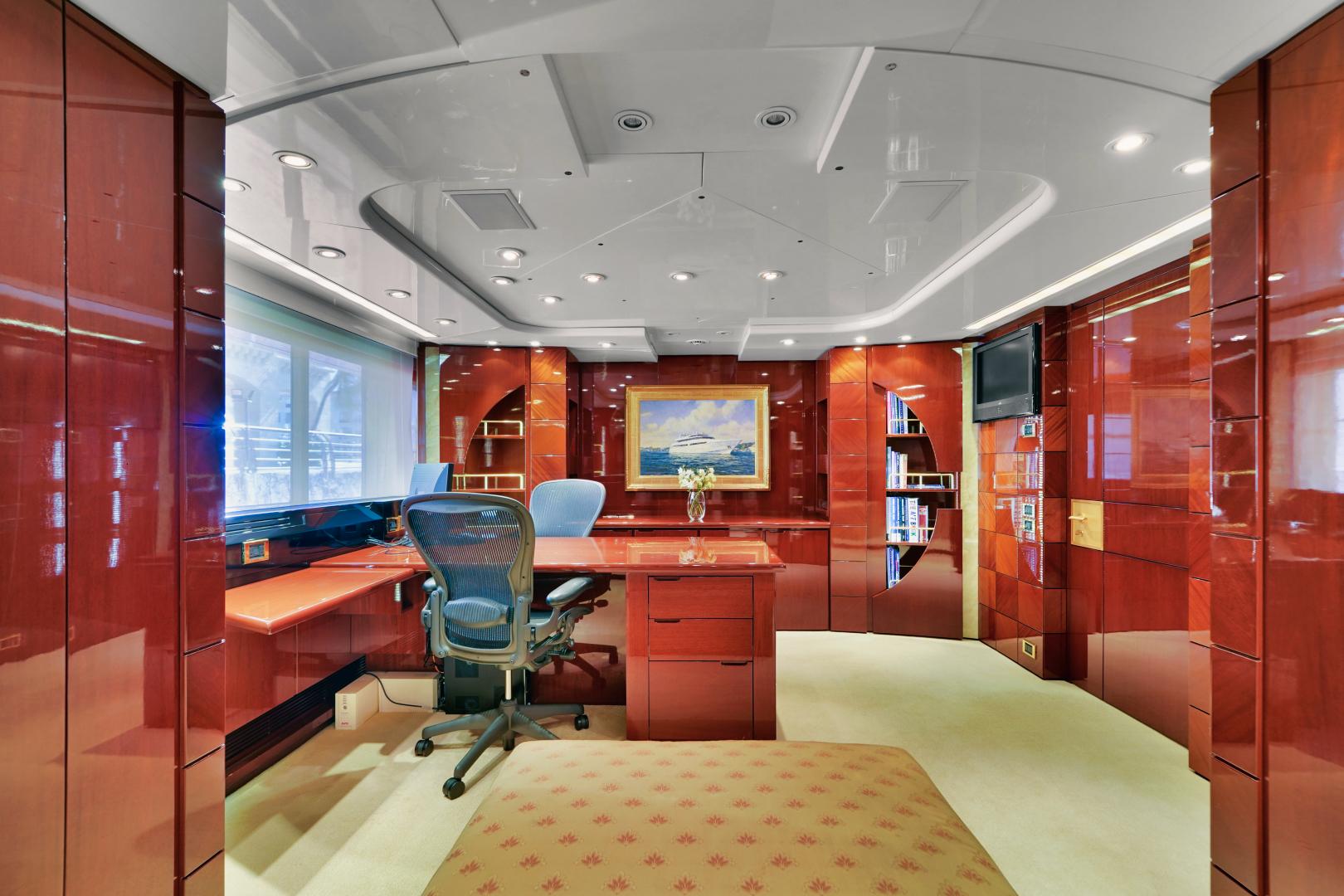

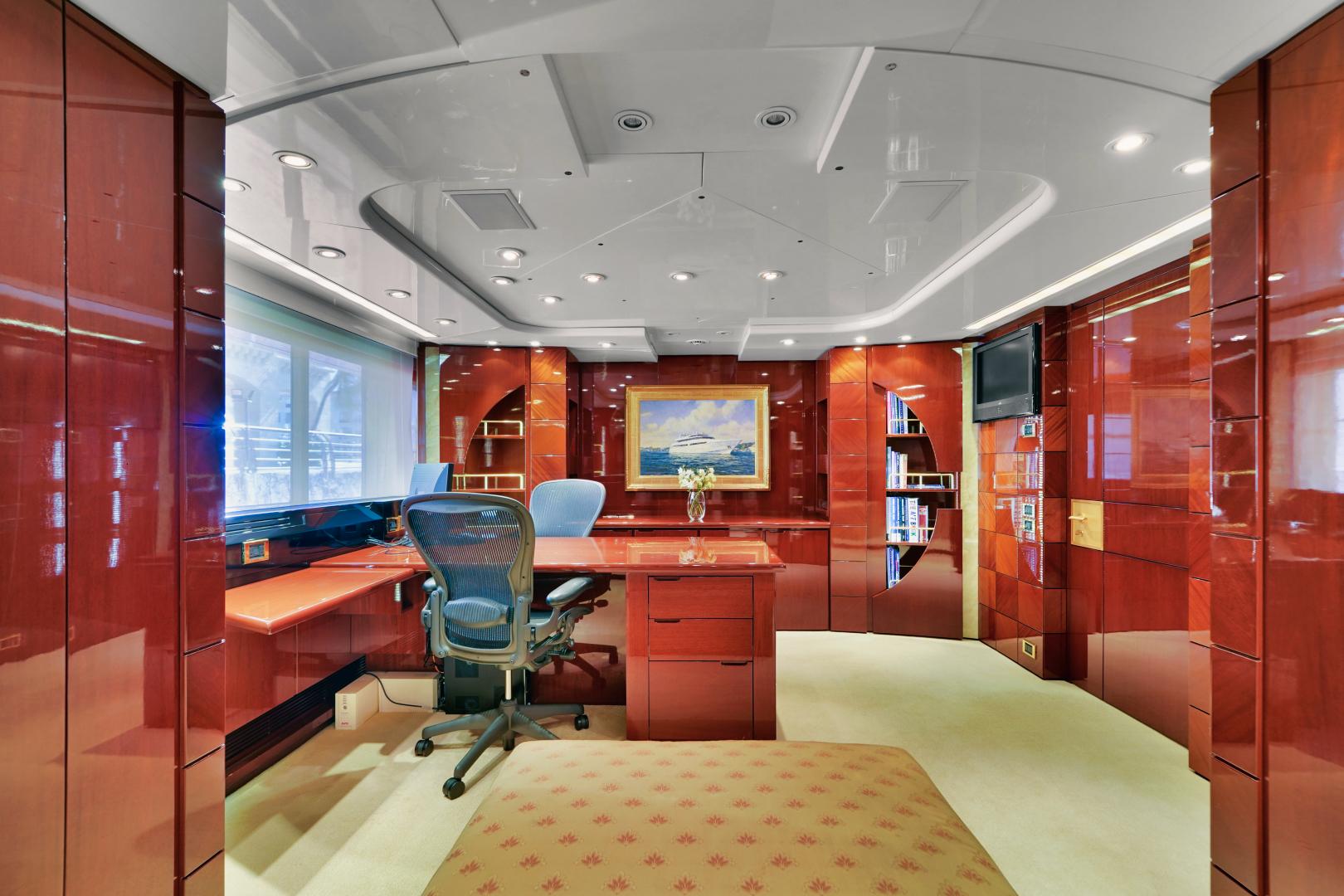

She has a nicely decorated interior, with cream carpets, beautiful high gloss mahogany cabinets and paneling throughout, with quality soft furnishings and interesting artwork. The main salon provides the yacht’s formal reception area with a bar and card table forward, balanced by four seating quadrants each focusing on a beautiful solid oak octagonal coffee table. BAD GIRL also has an impressive dining room with tables that can extend to seat sixteen guests and stunning sea views from full length windows. Forward and above the main salon, stairs rise to an observation lounge, which can be transformed into a cinema.

There are vast amounts of deck space, well laid out for a variety of outlooks on three levels. There is a nicely laid out area aft of the main for alfresco drinks and dining, while the upper deck is ideal for large-scale dining with 2 tables that can join together for grander entertaining.

Accommodations

Master cabin with his and her bathrooms, gym with sauna, and a private office. Two VIP double cabins with ensuite bathrooms, 3 twin cabins with ensuite bathrooms and 2 pullman berths in each cabin, and one small double cabin with shower ensuite. The master suite on the main deck has his and her bathrooms, an owner’s study, and a gym and sauna. This entire area can also be partitioned off from the main body of the yacht in several different styles to provide increased or lesser levels of privacy and intimacy.

Each cabin is well appointed and offers the ideal place to rest after a long day of exploration.

You’ll find an array of leisure and entertainment facilities onboard, making her ideal for entertaining friends and family on your charter vacation. There’s lots of space for enjoying an alfresco lunch or dinner on deck, or simply lounging in the sunshine and working on your tan.

Bad Girl is built to comply to MCA and Lloyds Register standards. She has a cruising speed of 15 knots, and a maximum speed of 25 knots, offering an ideal mixture of performance and style.

This impressive yacht comes complete with a modern stabilization system to reduce roll motion even during rough seas, and the yacht also has ‘at anchor stabilizers’ to keep things smooth even at anchor/zero speed.

A jacuzzi on deck is just perfect for relaxing with friends and family, while taking in the breath-taking scenery after a long day of exploration.

Wi-Fi connection is available throughout, so you’ll be able to stay connected while you’re away, great for business,

Basic Specs

Name: “BAD GIRL”

- Official Number: 721917

- Port or Registry: Hamilton, Bermuda

- Builder: Brooke Marine/Abeking & Rasmussen

- Type of Vessel: Commercial

- Signal Letters: ZCBC9

- Construction Material: Aluminum

- IMO Number: 1001192

- Keel Laid: October 1989

- Date Measured: July 1991

- Gross Tonnage: 709

- Net Tonnage: 212

- Classification:

- Lloyds Register of Shipping 100 A1A, Maltese Cross LMC.ISP,MCA

- MCA: Large Yacht Code for Commercial Charter Yachts – In compliance with LY2

Main Engines & Exhausts:

Engines rebuilt in 2013

The yacht is provided with three (3) main diesel engines.

- Three (3) MTU sixteen (16) cylinder 16V396 twin turbocharged four-stroke cycle highspeed

- diesel propulsion engines, operating on diesel or marine gas oil (“MGO”).

- Maker: MTU

- Model: 16V396

- Serial Numbers: Port: 5590629 Center: 5590630 Starboard: 5590631

- Operating hours: Port: 17508 Center: 7204 Starboard: 17507

- The following are additional basic details of the main engines:

- Mounting: Flexibly mounted atop engine side girders

- Gear Box: Close coupled

- Starting: Battery

- Controls: MTU Electronic control with throttle / gear controls at

- wheelhouse, wing stations and engine side

- Cooling: Jacket and charge air coolant fresh water

- Seawater plate type heat exchangers via attached

- centrifugal pumps.

- Lube oil pump: Integral

- Fuel strainers / filters: Racor triplex MA 1000

Marine Gears:

The yacht shaft lines are provided with reverse reduction gears. The gears were externally visually examined.

- Manufacturer: ZF

- Gear Model: BU 755

- Ratio: 3.321 to 1 (pt/stbd) 2.793:1 (ctr)

- Serial Number: Port: 307GGL Center: 301GGL Starboard: 306GGL

- Gear oil pump: Primary (input) gear driven

- Clutch: 24 VDC electric controlled hydraulic on input and reverse

- Thrust bearing: External – see “Running Gear”

- Controls & indicators: Gearbox side with indicators

- Engine local operating panels

- Wheelhouse main and wing consoles

Running Gear:

There are three (3) KaMeWa water jets as part of the yacht’s original machinery outfitting. The following are main details:

- Number: Three, Port and starboard turning, center fixed boost jet

- Material: Stainless Steel six bladed impellers

- Struts: One single leg and one vee strut per shaft

- Bearings: single pillar block per shaft

- Drive seals: Mechanical, water cooled

- Earthing: Brush system on each shaft

Stabilizers:

The vessel is fitted with active fin stabilization. Fin actuators are located in watertight compartments easily accessible from the tank deck via hinged watertight hatches.

- Manufacturer: Quantum Marine

- Type: At anchor “Zero Speed” hydraulic-fixed fin

- Actuator model: QC 1800 XT

- Rams: 2 x per actuator

- Location: Under guest bunks

- Fins: Steel foil shaped – area not determined

- Power pack: QP 2020CD

- Hour meter: 7621

- Control panels: ARC 3001 MK2 Bridge

Main Generators:

- Manufacturer/Assembler: Mercedes Benz

- Type: 10V183

- Location: Engine Room aft port/starboard in sound enclosures

- Rating gen sets: 184 eKW / 380 VAC 50 Hz. 3-phase 0.8 pf

- Starting system: Battery

- Cooling: Sea Water Cooled Heat Exchanger

- Engine Serial Numbers:

- Generator port: 423.900-000-521445

- Generator stbd.: 423.900-000-521447

- Generator Port hours: 52332 hrs, complete rebuild @ 43000

- Generator Starboard hours: 49688 hrs, complete rebuild @ 41616

Main Generator:

The yacht is fitted with an oil water separator in the engine room forward starboard:

- Manufacturer: Facet International

- Alarm: Deckma OMD-2005, 15 ppm(last serviced 19 Mar 2013)

- Location: Starboard Forward ER

- Meets IMO MEPC 107(49)

Fuel Filling & Transfer Systems:

The yacht is fitted with a fuel (diesel or marine gas oil “MGO”) filing and transfer system, as well as a fuel service system. The fuel filling and transfer system accepts fuel from the bunker fueling stations, port and starboard main deck bulwark, just aft of mid ships. The fuel enters the fill stations passing through a Tokico fuel meter to the distribution manifold located in the forward engine room port side. From there it can be disbursed to tanks No.1-No.7. Fuel tanks No.8 and No.9 respectively need to be filled and transferred via independent pumps through tanks No1. and No.4 respectively. The generators are provided fuel via a small service tank with independent transfer pump that starts automatically when the generators start. The principal equipment of the fuel oil system was visually examined and includes:

- Fuel Filling & Transfer

- 10 total - fuel storage / service tanks

Diesel Fuel:

- No.1 Port outboard Fr 12-17 8313

- No.2 Port Inboard Fr 12-17 12,400

- No.3 Starboard Inboard Fr 12-17 12,400

- No.4 Starboard Out Board Fr 12-17 8313

- No.5 Port Fr 17-20 11,732

- No.6 Starboard Fr 17-20 11,732

- No.7 Centerline Fr 36-39 11,637

- No.8 Converted Ballast Tank Fr 20-23.5 16,110

- No.9 Converted Ballast Tank Fr 20-23.5 16,110

- Fuel oil service tank Fr 11-12 3132

- Fuel bunker stations port/starboard, aft of mid-ships in outer bulwarks.

- Tokico Fuel meter

- Transfer manifold with valves

- 2 x fuel transfer engine room forward port

- 2x fuel transfer pumps forward port and starboard for tanks 8&9

- 1x tender transfer pump

- Electronic tank level indicating system

- Remote quick closing valves at tank outlets

- Fill / transfer piping

- Tank vent piping

- Tender fueling system in port Transom Locker

Fuel Service System

- FO settling and day tanks (incl. abv)

- Alfa laval centrifuge

- 1 x tender fueling system with electric pump

- Racor triplex primary fuel filters MA 1000’s for main diesel engines

- Racor duplex primary fuel filters MA 1000’s for generator diesel engines

- Remote quick closing valves at tank outlets

Water Makers:

The yacht is equipped with two (2) reverse osmosis freshwater maker units. The units were visually examined but were not in use as the yacht was in port. Principal details of the water makers include:

- 2x FCI @3100GPD

- Model NM31353S

- MFG: 3/2/2010

- S/N: Port: 3811, Starboard: 3810

Each unit has an independent sea suction, low-pressure supply pump and high-pressure membrane pump. Supply water from sea chest flows through a series of media filters prior to the membranes. Discharge from the water makers is to the forward holding tanks. Additionally, the tanks can be filled by two fill locations and one fill location through a water softener.

Air Conditioning and Ventilation:

AC system rebuilt in 2021

The yacht is provided with air conditioned / heated accommodation, service and technical spaces. The system is based on the chilled water fan coil principle, with main air handlers treating the re-circulated and fresh intake air to meet the design performance specifications. The components were visually examined as accessible, seen in use in the air conditioning mode, and found satisfactory. Principal details include:

- Principal Sub-Contractor: Carrier

- System Assembler / Manufacturer: Carrier

- Capacity: 30,000 BTU’s

- HVAC Monitoring & Control

- The system is controlled and monitored locally at the fan coil controllers and engine room.

- HVAC Chiller Plants

- There are two (2) central compressors and condensers but only one chiller plant for

- cooling / heat exchange. This duplication provides backup service provided the problem

- isn’t with the chiller. Main details include:

- 2x carrier semi-hermatic reciprocating compressors

- Refrigerating – R22

- 2 x chilled water pumps

- 2 x sea water pumps

- 2 x Shell and tube condensers

- 1x chiller

- 1x electric two stage 29 and 43 kw

Fan Coil Units

There are multiple air handler units for heat exchange / air treatment. These units are located throughout the vessel to provide effective cooling and heating. Heating is provided by a two-stage electric heater the re heats the chilled water total heating capacity 72kw.

Ventilation - Mechanical Supply & Exhaust

Mechanical supply and exhaust ventilation is provided in locations where heat is generated by the operation of equipment and appliances, or air exchange is otherwise desired. Extraction ventilation is provided for otherwise air-conditioned spaces in order to provide for fresh air exchange. Ventilation systems are provided for the following:

- Engine room

- Technical spaces

- Forepeak

Exhaust fans serving engine control room, galley laundry dryers, technical spaces, bow thruster room, Forepeak, accommodation spaces.

AC Sources:

New Atlas in 2013

The yacht is provided with two (2) main diesel generator sets for normal service, and one (1) emergency diesel generator set for the tender crane. Shore power connection is provided via 1 x shore cable.

- Main generators: 2 x 185kW 380VAC 50 Hz 3 phase

- Shore power: 1 x 75 kVA Atlas

The yacht is provided with a variety of safety equipment and arrangement, consistent with LR classification and Bermuda flag administration requirements. The yacht is certified for the carriage of up to 12 passengers and 16 crew.

The below listed safety equipment and arrangements were visually examined, tested as considered appropriate and found satisfactory. Items requiring annual or biennial service were being serviced at the time of the examinations. Related regulatory and service certificates were sighted and found in good order.

- Remote Ventilation shut-off (for accommodation and service spaces)

- Fire damper (for accommodation and service spaces)

- Fire damper (for machinery spaces)

- Remote control for fire dampers (for accommodation and service spaces)

- Remote control for fire dampers (for machinery spaces)

Fire Protection

- 3 Fire-protection appliances plan

- 1 Remote control for fire pump

- 1 Bilge and fire pump- centrifugal pump with self-priming unit

- 1 emergency fire pump- centrifugal pump with self-priming unit -20 m3/h; 6 bar

- 1 Remote control for fuel oil valves

- 1 remote release station CO2 (galley induction hood)

- 1 remote release station local application fire-extinguishing system (water)

- 1 international shore connection

- 7 Fire hydrant

- 2 Main section valves for fixed local fire-extinguishing system (water)

- 3 remote controls for fixed local fire-extinguishing system (water)

- 7 fire hose 20 m and nozzle

- fire extinguisher power 6 kg

- fire extinguisher CO2 5kg

- 1 wheeled fire –extinguisher foam 45 L

- 2 fire blankets

- 3 fixed local application fire-extinguishing system (water)

- 1 emergency generator

- 2 Air Compressor for breathing devices

- 2 control panel for fire detection and alarm system

- 1 push button/switch for general alarm

Life Saving Appliances

- 3 plans for life-saving appliances and means of escape

- 1 Rescue Boat Not approved for service at this time

- 5 life rafts

- 2 life buoys

- 2 life buoys with line

- 2 life buoys with light

- 2 life buoys with light and smoke

- 37 life jackets

- 6 child’s life jackets

- 1 assembly stations

- 2 search and rescue transponder

- 12 rocket parachute flares

- 4 line throwing appliance

- 3 two-way VHF radio telephone

- 2 emergency position-indication Radio Beacon (EPIRB

- 33 immersion suits

- 7 emergency escape breathing device (EEBD)

Other firefighting equipment / arrangements include:

- Fire main with hydrants, hoses, nozzles and wrenches (tested)

- 1 x main electric fire / bilge pump (tested)

- 1 x emergency diesel fire / bilge pump (tested)

- Fire detection & alarm system (tested)

- Portable and semi-portable fire extinguishers

- Ventilation shutdowns, dampers / closures (tested)

- Emergency and low-level lighting (tested)

- International shore connection

Bridge Console:

- magnetic compass

- 2x Furuno Radar

- Anschotz gyro compasses

- Anschotz Autopilot

- Furuno Doppler speed log

- B&G Hydra 2000

- Interphase forward looking sonar

- Furuno FCV 014 Sonar

- EC-I Transas, Navi Sailor 3000 18” Sony monitor

- 2 x Furuno GPS

- Furuno Sailor VHF

Wing Stations:

- B&G H2000

- Intercom set

GMDSS Station:

- 2 x Satcom C

- Furuno VHF

- Fruno HF/MF

- Navtex

- SART

Crew Mess:

- Thorne smoke alarm monitor

Captains Office:

- Sailor VHF

- Skanti SSB

Black Water (Sewage) System:

The yacht is fitted with a vacuum type black water drain system for guest accommodations and vacuum heads for crew. The system was seen in use and where accessible, visually examined. Principal details of the black water drain system include:

- Vacuum toilets in guest accommodation to vacuum tanks/ vacuum toilets in crew

- 2 x Jets 3.5 kW vacuum macerator pumps

- Hamann Waste treatment system with chlorine injection

- Capacity: 816 kg per day

- Holding tank for treated waste

Refrigeration / Provision Cooling:

The yacht is provided with mechanical refrigeration system for provision cooling and storage. The principal details include:

Refrigeration Cooling Plant

- Located above bow thruster compartment

- 2 x Copeland Model KAJA-011E TAD800 compressors

- 2 x Marine Service condensers

- 2 x sea water pumps- Crew mess bilge

Cold Rooms:

Cold rooms are stainless steel lined with lighting, air circulation fans and heat strips on the doors. Doors are heavily fabricated with good latches. Cold room and freezer are forward of the crew accommodations deck.

- Walk in Cold Room Starboard side Fwd

- Freezer starboard side Aft

- Air coolers in overheads of each compartment

- Heat strips on doors and interior lighting

- Control by alarms and monitoring system to central monitoring system.

Ground Tackle & Mooring Equipment:

The yacht is provided with ground tackle and mooring equipment. It was visually examined at this time and found satisfactory. The main details are as follows:

Anchors, Windlasses & Chains

The yacht is equipped with two (2) semi balanced HHP anchors that stow flush in recessed pockets with stainless steel striker plates.

- 2 shipyard supplied hydraulic anchor vertical windlasses - capstans

- Controls – handheld wandering leads

- Hand brakes

- Chain rollers

- Riding pawls and devil claws

- Enclosed chain lockers

- Inboard bitter end chain releases

- 2 x Noah Bloomer anchors, 141 kg each

Mooring Equipment & Fittings:

The yacht is equipped with various gear for mooring the vessel.

- 2 hydraulic mooring capstans with foot switches

- 4 x double bitts, polished stainless steel main deck aft

- 1 x double bitt, polished stainless steel with stopper eyes at main deck port and starboard midships

- 4 x double bitts polished stainless steel with stopper eyes at foredeck

- 4 x mooring line fairleads foredeck

- 2 x mooring rollers on foredeck

Foredeck Rescue Boat Crane:

On the foredeck centerline with base to starboard there is a hydraulic crane. hatch with contains the rescue boat crane controls. The hatch and crane operation are interlocked. The unit can be run off the main and emergency generator.

- MFG: Aqua Crane

- Rating / Capacity: 750 kg. SWL (reported)

- Reach/rotation: 4 meters – 345 degrees

- Cable: 10 mm steel 28 x 7 non-rotating

- Hook: SS

- Controls: Wire control unit

- Manual hydraulic at unit

- Power Pack: located in stbd fore deck locker.

Passarelle:

- Material: Aluminum with teak deck, ss rails

- SWL: 250 kg.

- Length: approx. 5.5 meters beyond swim platform

- Functions: up/down

- Controls: Local control panel

- Overhead Sliding Beam Gantry Cranes

- Crane Location: Port & stbd. Tender bays– 1 per side

- Construction: Stainless steel - hydraulic

- Port Rating capacity: Not posted

- Stbd. Rating capacity: Not posted

- Controls: Wire remote

Bad Girl has been inactive for about 6 years, two years in Mobile, Alabama and four years in Cap Cana, Dominica Republic, all the while being maintained by a small crew. The estate has been settled and Bad Girl is ready to be sold.

ABS layup surveys were completed as required by ABS, the most recent was in June of 2021. An insurance survey was completed in 2019 and a bottom survey was completed in June of 2021.

The entire AC system was rebuilt in 2021. The engines were recently surveyed by an MTU technician. All recommended services are being scheduled. The Harmon waste system has had major upgrades in 2021.

The amazing crew has been fastidious about maintaining the interior woodwork and teak to a very high standard.

$5,400,000 is a low asking price for Bad Girl. The owners know that it is time to sell. After a yard period, Bad Girl will offer the new owner years of amazing adventures at a fraction of the price of similar yachts.